Chemical engineering turns raw materials into valuable products using chemistry, physics, and biology¹. It develops systems that are efficient, scalable, and safe to operate in real industrial environments. Chemical engineering plays a central role in many industries and is evolving to meet the changing needs of global industries. Let's explore what it is.

Defining Chemical Engineering

Chemical engineering is one of the main types of engineering that turns raw materials into products through chemical, physical, and biological processes¹. While it has the word "chemical" in its name, it combines chemistry, physics, mathematics, and engineering design to develop safe, efficient, and scalable manufacturing systems². So many products in modern life, from fuel and medicine to food and renewable materials, rely on chemical transformations¹, which means chemical engineering is a key part of industry and global sustainability efforts.

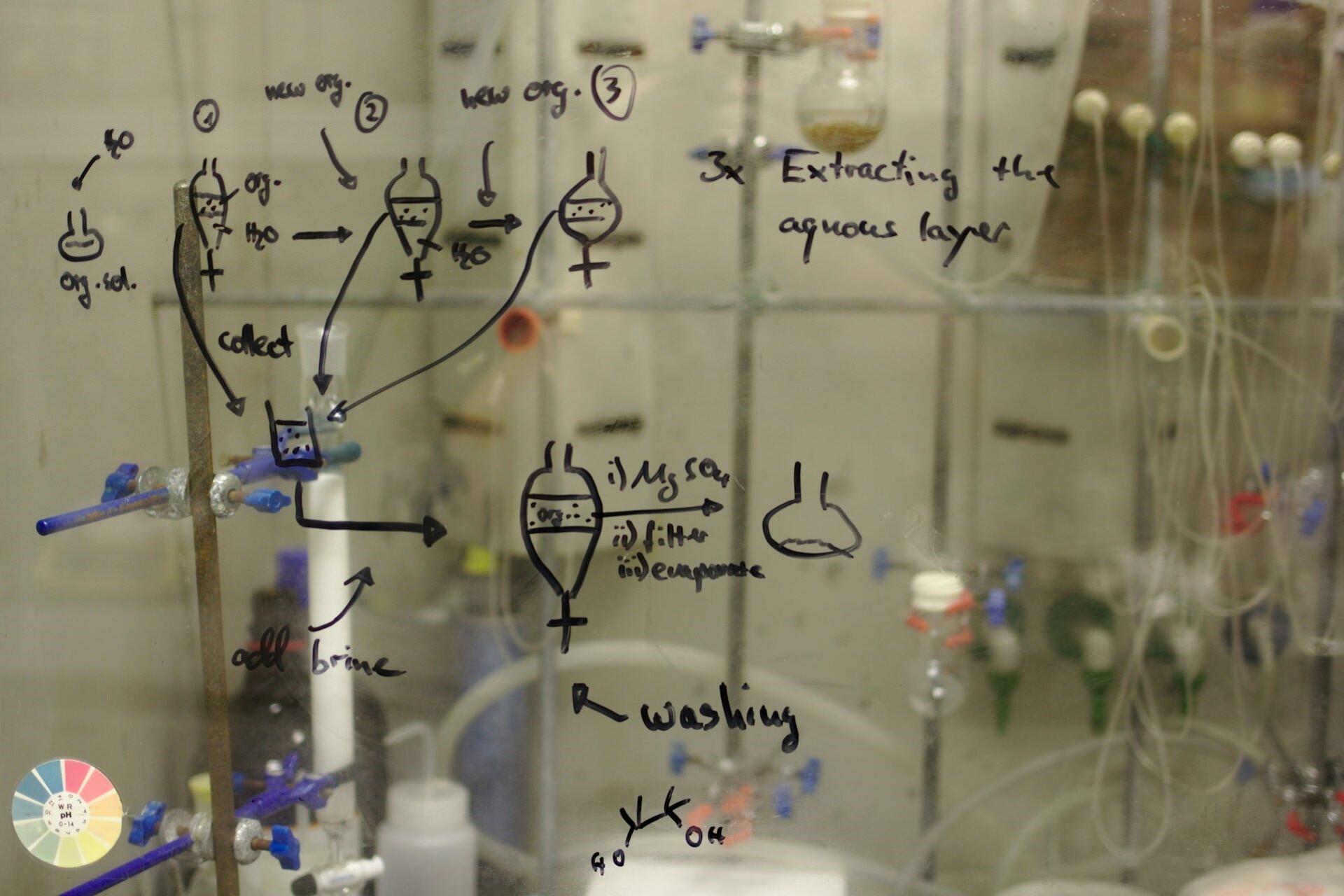

Chemical engineering is not just lab chemistry; it involves designing large-scale industrial processes that convert raw materials into products safely and efficiently⁵. Chemical engineers work to improve reaction conditions, design equipment, prevent hazards, and ensure that industrial processes meet environmental and safety standards.

Core Principles and Concepts

Chemical engineering is guided by fundamental scientific principles that explain how substances behave and how energy and materials move through systems³. Every chemical engineer will likely be well-versed in most of these. The areas they'll likely study and specialise in include:

Historical Evolution

Chemical engineering developed from industrial chemistry as manufacturing processes became larger and more complex¹. Unlike the seemingly ancient field of civil engineering, chemical engineering is one of the newer branches of engineering², as much of what's happening isn't visible to the naked eye. While other branches of engineering date back to the earliest human civilisations, chemical engineering is much more recent.

The Development of Chemical Engineering

Mid-1800s

Early Industrial Chemistry

Large-scale production of chemicals such as acids and dyes begins, driven by industrial demand.

1880s

Birth of Chemical Engineering

The term chemical engineer emerges as engineers begin focusing on scaling chemical processes safely and efficiently.

1910–1940

Unit Operations Era

Chemical engineering becomes defined by processes such as distillation, filtration, and heat exchange — forming its core technical identity.

1950–1980

Process Systems Engineering

Computers and mathematical modelling introduce new methods for designing and controlling industrial systems.

21st Century

Sustainable and Biochemical Engineering

Growth in renewable energy, biotechnology, and environmentally responsible materials reshapes the field and expands new applications.

The Role of a Chemical Engineer

So, what exactly would a chemical engineer do during their work? Their role is to design and optimise processes that convert raw materials into valuable products safely, efficiently, and at an industrial scale¹. Their work is what bridges the gap between laboratory experimentation and real-world production.

Typical Responsibilities

Chemical engineers are typically involved across the lifecycle of chemical and industrial processes, from concept development to evaluation and optimisation⁵. They have to balance scientific understanding, practical engineering constraints, safety considerations, and production efficiency. Here are some of their typical responsibilities.

Work Environments

Just like the work of an electrical engineer, a chemical engineer's role, industry, and production scale will usually dictate where they work. Some chemical engineers work in research and development labs to develop new materials or improve reaction processes⁵. Others work on industrial sites, overseeing equipment, monitoring systems, and coordinating with operators and technicians¹.

Educational Pathways and Career Prospects

To become a chemical engineer, you need a strong foundation in chemistry, physics, mathematics, and engineering design². Chemical engineers work with complex systems that have to be both safe and efficient, which is why their formal training combines theoretical study with practical lab work and industry experience. Chemical engineers are required across so many sectors, making their career prospects broad.

Most chemical engineers begin with a Bachelor of Engineering (Honours) degree in Chemical Engineering or Chemical and Biomolecular Engineering. Coursework typically includes thermodynamics, reaction engineering, fluid mechanics, transport phenomena, and process design. Many programs include laboratory classes, team-based projects, and work-integrated learning placements to develop applied experience. Choosing a degree accredited by Engineers Australia is recommended to support professional recognition and future chartered membership.

Pathway to Becoming a Chemical Engineer

Step 1

Complete secondary school with strong performance in mathematics, chemistry, and physics.

These subjects provide the analytical and scientific foundation needed for engineering coursework.

Step 2

Enrol in a Bachelor of Engineering (Honours) with a chemical engineering major.

Typically, a four-year program with a mix of lectures, laboratory sessions, and group projects.

Step 3

Participate in industry placements or internships.

Work-integrated learning offers real-world experience and helps build professional networks.

Step 4

Graduate from an Engineers Australia–accredited program.

Accreditation supports eligibility for professional membership and international recognition.

Step 5

Begin work as a Graduate Chemical Engineer and continue developing technical competency.

On-the-job experience builds understanding of industrial processes and operational practice.

Step 6

Work toward Chartered Professional Engineer (CPEng) status if desired.

Chartership demonstrates advanced expertise and leadership in the profession.

Career Opportunities

Just like the varied work of mechanical engineers, chemical engineers are employed across multiple industries, giving them flexibility to work in fields aligned with their interests². Roles may involve research and innovation, plant operation, design consulting, production management, or environmental improvement. Career progression often leads to specialist technical roles, project leadership, or cross-disciplinary positions in sustainability, safety, or process optimisation.

for a chemical engineer in Australia².

Future Trends in Chemical Engineering

In response to global challenges, chemical engineering continues to evolve. Industries are moving towards lower-emissions processes and more efficient resource use⁵, which is why chemical engineers are increasingly involved in designing systems to minimise waste, reduce environmental impact, and support circular production models.

Technological Innovations

Emerging technologies are transforming how chemical engineering problems are approached and solved⁵. These developments enhance efficiency, accuracy, and sustainability across a range of industrial applications.

Key Areas of Innovation

Sustainability and Environmental Impact

Sustainability has become a core priority in chemical engineering, influencing how processes are designed, materials are selected, and energy is consumed. Engineers now focus on systems that minimise waste, reduce emissions, and conserve resources without compromising product quality or industrial output.

Chemical engineers directly influence how resources are used on an industrial scale. Optimising processes for efficiency and sustainability can reduce environmental impact while improving performance and lowering production costs.

Key Sustainability Focus Areas

References

- ChemEngZone. “What Does a Chemical Engineer Do?” https://chemengzone.com/what-does-a-chemical-engineer-do/

- Go Construct (UK). “Chemical Engineer Job Profile.” https://www.goconstruct.org/construction-careers/what-jobs-are-right-for-me/chemical-engineer/

- Chemical Engineering Site. “Transport Phenomena in Chemical Engineering – A Comprehensive Overview.” https://chemicalengineeringsite.in/transport-phenomena-in-chemical-engineering-a-comprehensive-overview/

- Fiveable. “Transport Phenomena — Introduction to Chemical Engineering.” https://fiveable.me/key-terms/introduction-chemical-engineering/transport-phenomena

- University of North Dakota. “What Do Chemical Engineers Do?” https://und.edu/blog/what-do-chemical-engineers-do.html

Summarise with AI: