Mechanical engineering is one of the most versatile and widely applied branches of engineering¹. The area focuses on how machines and mechanical systems are built and used. A combination of mathematics, physics, materials science, and computer-aided design, mechanical engineering enables innovation across industries, including aerospace, automotive, energy, and manufacturing².

Defining Mechanical Engineering

Mechanical engineering is the branch of engineering that focuses on designing, analysing, manufacturing, and maintaining machines, mechanical systems, and energy-conversion technologies¹. It draws on mathematics, physics, materials science, and thermodynamics to understand how forces and motion interact with physical structures². Mechanical engineers look to optimise the efficiency, reliability, and performance of systems from everyday household items to complex industrial machinery.

Core Principles and Concepts

Mechanical engineering draws on several core principles and concepts³. These include scientific and mathematical principles, the very same that you'd likely use if you choose to become a civil engineer, electrical engineer, or even a chemical engineer. Using these, mechanical engineers can understand how materials behave, how forces act on objects, and how energy is transferred within mechanical systems.

Historical Evolution of the Discipline

Mechanical engineering traces its roots to ancient technological innovations, including early tools, irrigation systems, and simple machines². However, it expanded greatly during the Industrial Revolution, spurred on by advances in steam power, metalworking, and manufacturing processes. Nowadays, it continues to evolve alongside computing, automation, and advancements with new materials, with the fields of mechanical engineering and electrical engineering working together on the latest advancements.

Development of Mechanical Engineering

Before 500 CE

Early Mechanical Foundations

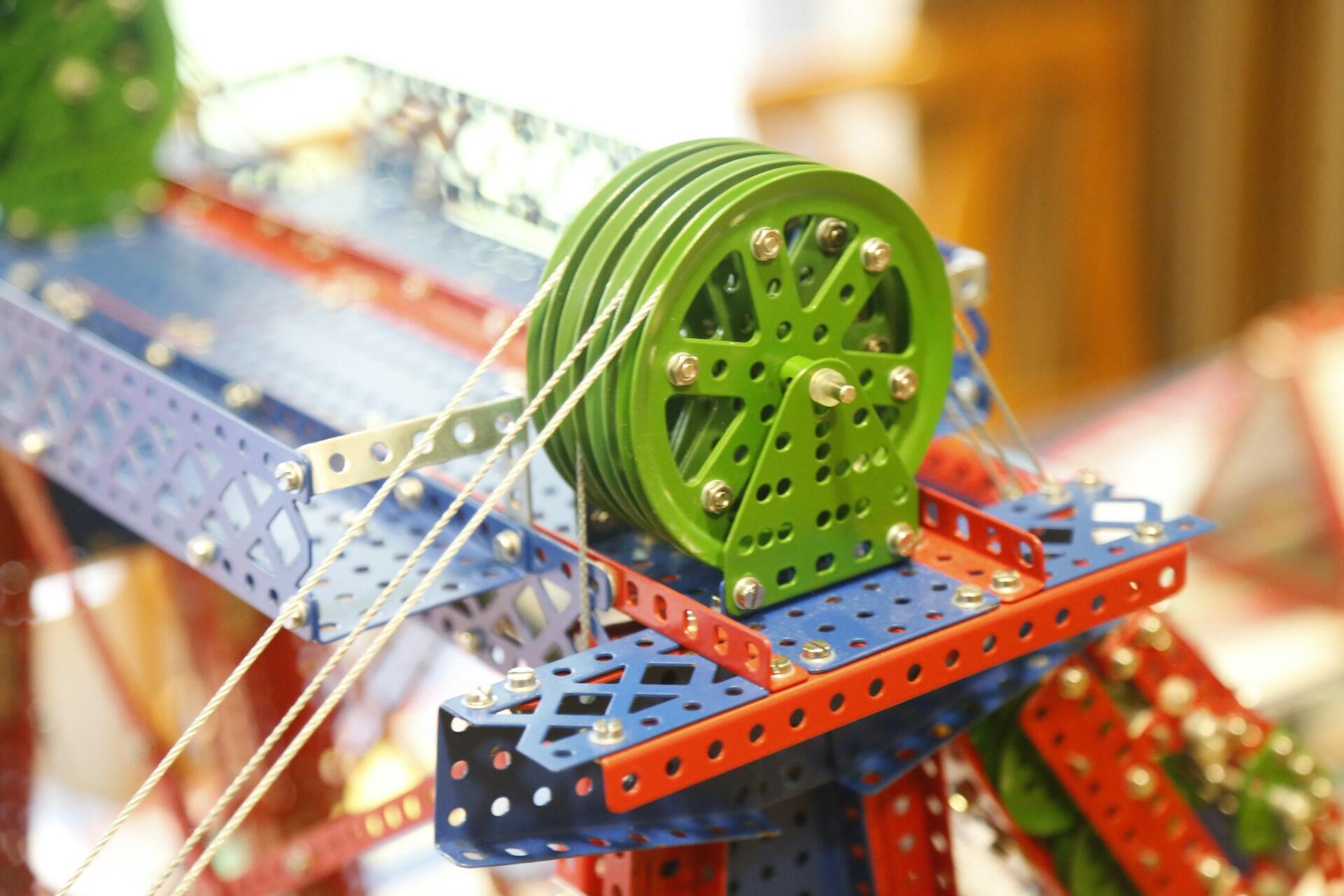

Civilisations including Egypt, Greece, China, and Mesopotamia developed basic mechanical devices such as levers, pulleys, gears, and water wheels, laying the foundations for mechanical systems.

1200–1500 CE

Inventive Mechanisms and Automata

Innovators like Al-Jazari and Leonardo da Vinci designed automata, hydraulic mechanisms, clockwork machinery, and early conceptual machines, demonstrating a deeper understanding of motion and control.

1760–1830

The Industrial Revolution

The refinement of the steam engine by James Watt revolutionised manufacturing and transportation. Mechanisation led to the rise of large-scale factories and marked the emergence of mechanical engineering as a formalised discipline.

Mid–Late 19th Century

Professionalisation of Engineering

Universities and technical institutions began offering engineering education. Mechanical engineering societies formed, establishing shared standards, ethics, and professional identity.

Early 20th Century

Mass Production and Motor Age

The development of internal combustion engines and assembly line production transformed industries such as automotive manufacturing, increasing the demand for mechanical engineering expertise.

Late 20th Century

Digital and Computational Advances

The introduction of CAD, computer simulation tools, and finite element analysis fundamentally changed how engineers design, test, and optimise mechanical systems.

21st Century–Present

Advanced and Sustainable Systems

Mechanical engineering now intersects with robotics, biomedical engineering, renewable energy, aerospace, and nanotechnology, with growing emphasis on automation and sustainability.

Roles and Responsibilities of Mechanical Engineers

Mechanical engineers are involved in every stage of a mechanical system's lifecycle¹. From the initial concept and modelling to fabrication, testing, and long-term maintenance, mechanical engineers bring analytical thinking, creativity, and practical problem-solving. Thanks to them, systems operate efficiently and safely.

Design and Development

Mechanical engineers design machinery, components, and mechanical systems based on performance requirements and real-world conditions¹. This involves developing technical drawings, selecting appropriate materials, and using computer-aided design (CAD) and simulation software to model how systems will behave under various forces. The design process balances reliability, safety, efficiency, and manufacturing cost, requiring engineers to apply their understanding of mechanics, thermodynamics, and materials science.

Analysis and Testing

Once a system has been designed, mechanical engineers conduct a detailed analysis to verify that it will function as intended¹. This may include evaluating stress, heat transfer, vibration, or fluid flow, depending on the system's purpose. They also test prototypes or existing machinery to identify weaknesses, ensure performance, and validate safety compliance. Testing allows engineers to refine systems before they are produced or deployed at scale.

Common Testing Focus Areas

Manufacturing and Maintenance

Mechanical engineers work closely with manufacturing teams to ensure that designs can be produced efficiently and to the required specifications. This includes selecting fabrication methods, developing assembly processes, and reviewing quality control standards. Depending on the project, they may work with chemical engineers, civil engineers, or electrical engineers. After systems are deployed, mechanical engineers may conduct inspections, schedule maintenance, and recommend repairs or upgrades. Their aim is to maximise performance over time while minimising downtime and cost.

Applications Across Industries

Since mechanical engineering focuses mainly on how systems move, produce energy, and perform mechanical work, it supports a wide range of industries². Mechanical engineers improve efficiency, reliability, and safety across a range of contexts. As we'll see later, this range of applications makes mechanical engineering a great career choice, too!

Mechanical engineers play a crucial role in designing vehicles, aircraft, and propulsion systems¹. In the automotive sector, they contribute to engine efficiency, aerodynamics, safety systems, and electric vehicle technology. In aerospace, they work on aircraft structures, turbine engines, flight-control mechanisms, and space exploration technology, where precision and reliability are critical.

Typical Work in This Area

Energy and Power Generation

Mechanical engineers support energy systems that power homes, cities, and industries¹. Their work spans conventional power stations, wind and solar installations, and emerging technologies like hydrogen systems and large-scale energy storage. They help improve efficiency, system output, and environmental performance.

Typical Work in This Area

Biomedical Engineering

In biomedical settings, mechanical engineers help create devices and systems that interact with the human body². This includes artificial joints, prosthetics, diagnostic equipment, and surgical instruments. The work requires careful attention to materials, ergonomics, and biocompatibility.

Typical Work in This Area

Robotics and Automation

Mechanical engineers design robotic systems and automated machinery used in manufacturing, logistics, medicine, and research². They develop mechanisms, actuators, and motion-control systems that allow machines to move and perform tasks accurately. This field frequently overlaps with software engineering, electronics, and artificial intelligence.

Typical Work in This Area

Educational Pathways and Skills Required

Like other engineering disciplines, mechanical engineering requires a combination of theoretical study and hands-on technical experience. It's common for engineers to begin with a university degree before gaining work experience either through specific programs or entry-level roles. Since engineering is a constantly evolving field, ongoing education is also recommended.

Academic Qualifications

A Bachelor of Engineering (Honours) with a major in mechanical engineering is the standard entry-level qualification¹. Programs typically include coursework in mechanics, thermodynamics, materials science, and design². It's common for programs to feature work-integrated learning or industry placements to gain some practical experience before starting work.

Universities Offering Accredited Mechanical Engineering Programs

Essential Skills and Competencies

Mechanical engineers combine scientific reasoning, technical software knowledge, and interpersonal skills. You won't gain all of these skills overnight, but by starting with an accredited program, you'll learn some of them. From there, these are the skills you should work towards developing:

Key Skills and Why They Matter

Career Prospects and Demand in Australia

Like most engineering roles, there are strong prospects for mechanical engineers in Australia⁵. Mechanical engineers are valued for their ability to solve complex technical problems while adapting to a wide range of applications. Mechanical systems are present in nearly every industrial sector, so employment opportunities are widespread around the country.

Current Job Market Trends

Mechanical engineers are commonly employed in industries such as construction, mining, energy generation, aerospace, defence, automotive systems, and advanced manufacturing⁶. Graduate positions are often available through structured programs at engineering firms, utilities, and government organisations. Mid-career engineers can move into design leadership, project management, or consulting roles as they gain experience and professional accreditation.

Emerging Opportunities

Emerging technologies are expanding the scope of mechanical engineering and creating new career paths⁵. Growth areas include renewable energy system design, electric vehicle development, smart manufacturing and robotics, medical device engineering, and advanced materials research. Engineers who develop strong skills in automation, simulation, digital modelling, and energy efficiency are well-positioned to work in these fields. As industries continue to modernise, the ability to work with multidisciplinary teams and adopt new technologies will become increasingly valuable.

Future Directions and Innovations

As mechanical engineering continues to evolve, new technologies are reshaping how systems are designed, tested, and manufactured. The field is being increasingly influenced by digital tools, sustainability initiatives, and more efficient, adaptable mechanical systems. Industries are generally moving toward automation and low-carbon solutions, with mechanical engineers playing a key role in developing high-performing and environmentally responsible technologies.

Advancements in Materials and Technology

New materials and fabrication techniques are expanding the capabilities of mechanical systems. Lightweight composites, high-strength alloys, and advanced polymers allow engineers to create components that are stronger, more durable, and more efficient. Additive manufacturing (3D printing) has also transformed prototyping and production, enabling the production of custom parts, reducing waste, and enabling rapid iteration. These materials and manufacturing advances support innovation in aerospace, medical devices, automotive systems, and renewable energy infrastructure.

Emerging Material Technologies

Integration with Digital Technologies

Digital tools are now fundamental to modern mechanical engineering. Simulation software and digital twins allow engineers to model system behaviour before anything is built, reducing development time and cost. Meanwhile, automation and robotics are reshaping manufacturing and production systems. The rise of smart sensors and data analytics has enabled predictive maintenance and real-time system optimisation.

The integration of simulation, automation, and sensor-based monitoring improves system performance, reduces downtime, and creates more efficient workflows across manufacturing and energy sectors.

References

- Bureau of Labor Statistics (U.S.). “Mechanical Engineers: Occupational Outlook Handbook.” https://www.bls.gov/ooh/architecture-and-engineering/mechanical-engineers.htm

- Michigan Technological University. “What Is Mechanical Engineering?” https://www.mtu.edu/mechanical-aerospace/mechanical-engineering/

- Bryan Hackleman Engineering. “Core Mechanical Engineering Principles Every Engineer Should Know.” https://bryanhackleman.com/core-mechanical-engineering-principles-every-engineer-should-know/

- SEEK Australia. “Mechanical Engineer Salary.” https://www.seek.com.au/career-advice/role/mechanical-engineer/salary

- Engineers Australia. “The Engineering Labour Market Overview (August 2024).” https://www.engineersaustralia.org.au/sites/default/files/2024-09/The-Engineering-Labour-Market-Overview-August-24.pdf

- National Careers Service (UK). “Mechanical Engineer Job Profile.” https://nationalcareers.service.gov.uk/job-profiles/mechanical-engineer

Summarise with AI: